Services

Discover our

main three benefits

Maximum coverage

Fibre blown insulation is installed by mechanically blowing loose fibres into the desired space — whether it's a loft, timber frame building, or floor void. This process allows the material to flow and settle into every corner, crack, and crevice, creating a seamless layer of thermal protection.

Why It Matters:

- No Cold Spots: Traditional insulation (like batts or boards) often leaves small gaps or irregular coverage, especially around pipes, wiring, and uneven joists. These gaps can cause “cold bridging,” where heat escapes through uninsulated areas.

- Consistent Thermal Barrier: Fibre blown insulation forms a uniform layer that helps maintain a consistent indoor temperature, improving comfort and reducing reliance on heating systems.

- Enhanced Airtightness: While not a substitute for air barriers, blown fibre insulation reduces uncontrolled air movement, especially in attics and suspended floors.

- Minimised Material Waste: Because it adapts to the space, there’s no cutting or offcuts, making it both efficient and environmentally friendly.

This maximum coverage is a key reason why fibre blown insulation can outperform traditional methods in real-world conditions — not just in lab-tested R-values, but in how it performs over time in your home.

Eco-thinking

Fibre blown insulation stands out for its strong environmental credentials. Many of the materials used — such as cellulose, wood fibre, and mineral wool — are made from recycled or natural resources, making them a sustainable choice for homeowners and businesses alike.

Why It’s Important:

- Reduces Waste: Cellulose blown fibre is typically made from recycled newspapers, diverting tons of paper from landfills. Mineral wool often incorporates industrial by-products like slag.

- Lower Carbon Footprint: Natural fibres require less energy to manufacture than synthetic materials like rigid foam or plastic-based insulation. This results in lower embodied carbon for your building project.

- Safe and Non-Toxic: Natural fibre products are typically treated with non-toxic fire and pest retardants, making them safer to install and healthier for indoor air quality.

- Supports Green Building Standards: Choosing eco-friendly insulation supports compliance with Passivhaus criteria, and helps future-proof homes against tightening energy regulations.

By offering blown fibre products that are kind to the planet without compromising on performance, we help customers make smarter, greener choices for their homes — today and into the future.

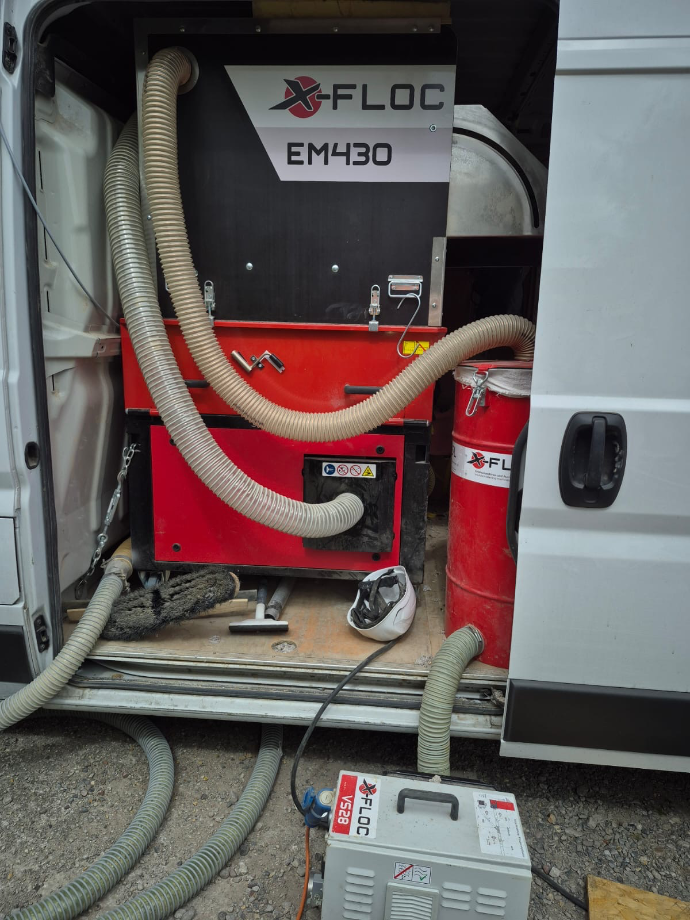

Simple and effective installation

One of the standout advantages of fibre blown insulation is its speed and simplicity — particularly when insulating internal partition or stud walls. Whether you're retrofitting insulation for thermal efficiency, acoustic privacy, or both, fibre blown solutions offer a low-mess, high-efficiency alternative to traditional methods.

Why It’s Important for Internal Walls:

- No Full Wall Removal: Fibre blown insulation is injected through small access holes (which are later patched), so there's no need to remove drywall or plasterboard — unlike traditional batt or board insulation.

- Fast Turnaround: Ideal for busy households, office spaces, or renovation timelines.

- Less Dust and Debris: The process produces minimal disruption to the interior environment, with virtually no cutting or sawing required. It’s ideal for occupied homes or commercial settings.

- Preserves Finishes: Since walls don’t need to be opened up, there’s less risk of damaging finishes like paint, wallpaper, or built-in features — saving on redecorating costs.

- Ideal for Retrofits: Perfect for upgrading older buildings where internal wall cavities already exist but are uninsulated or underperforming.

Cellulose Fibre Blown Insulation

Cellulose fibre insulation is a sustainable, loose-fill material made primarily from recycled paper products, most commonly newspapers. It is one of the most eco-friendly insulation options available and is typically used for lofts, walls, and floors due to its excellent thermal and acoustic performance.

85%

Cellulose Fibre Blown Insulation can be made from up to 85% recycled content

Key Attributes

- Eco-Friendly: Great option for eco-conscious retrofits and new builds aiming for Passivhaus or low-carbon standards.

- Effective Thermal Performance: With typical constructions achieving U-values between 0.30 and 0.09 W/m²K.

- Good Acoustic Insulation: Dense structure reduces airborne noise.

- Fire-Resistant: Treated with natural mineral salts (such as borates) to resist fire, mould, and pests.

- Breathable: Helps manage moisture and humidity, supporting healthier indoor environments.

Wood Fibre Blown Insulation

Wood Fibre Blown Insulation is a carbon-negative, loose-fill wood fibre insulation made from recycled wood chips sourced from sustainably managed forests. Designed for use in timber frame construction, it can be blown into enclosed cavities within walls, roofs, ceilings, and floors, as well as used as a loose layer over loft spaces.

Key Attributes

- Carbon-negative insulation made from recycled wood chips

- Ideal for timber frame walls, roofs, floors, ceilings, and lofts

- Blown-in for a seamless fit with no air gaps or cold bridges

- Fills around pipes, cables, and awkward spaces easily

- Excellent thermal performance – warm in winter, cool in summer, achieving U-values around Roof U-value: 0.13W/m²Kand Wall U-value: 0.15 W/m²K

- Highly breathable – manages moisture and prevents mould

- Contains 5% ammonium salts acting as a fire retardant – causing the insulation to char rather than igniting, enhancing fire resistance.

- Made from sustainably sourced wood and helps reduce CO₂

Mineral Fibre Blown Insulation

Mineral fibre blown insulation is a loose-fill insulation material made from spun glass or stone mineral fibres. It is blown into cavities—typically in external masonry walls—using specialist equipment to create a seamless, full-fill thermal barrier.

Highlights Key Attributes

- Fire Safety: Achieves Euroclass A1 classification, indicating non-combustibility, will not burn, produce toxic smoke, or contribute to fire spread.

- Moisture Resistance: Incorporates a water-repellent additive, preventing moisture ingress and capillary action across the cavity

- Low Emissions: Contains no ozone-depleting substances or greenhouse gases, contributing to a lower carbon footprint.

- Longevity: Designed to last the lifetime of the building, minimising the need for replacement.

- Thermal Conductivity: the U-value of fiberglass insulation typically falls between 0.030 and 0.040 W/m²K, delivering excellent insulation, helping to meet or exceed Part L Building Regulations and improving energy efficiency in homes and commercial buildings.

- Helps reduce condensation risk, improving building durability and indoor air quality.

Our Trusted Suppliers